SAFETY AND SECURITY FILM

- Home

- SAFETY AND SECURITY FILM

The purpose of safety and security films is to enhance the safety of glass by increasing its strength and preventing dangerous shards from spreading in case of breakage.

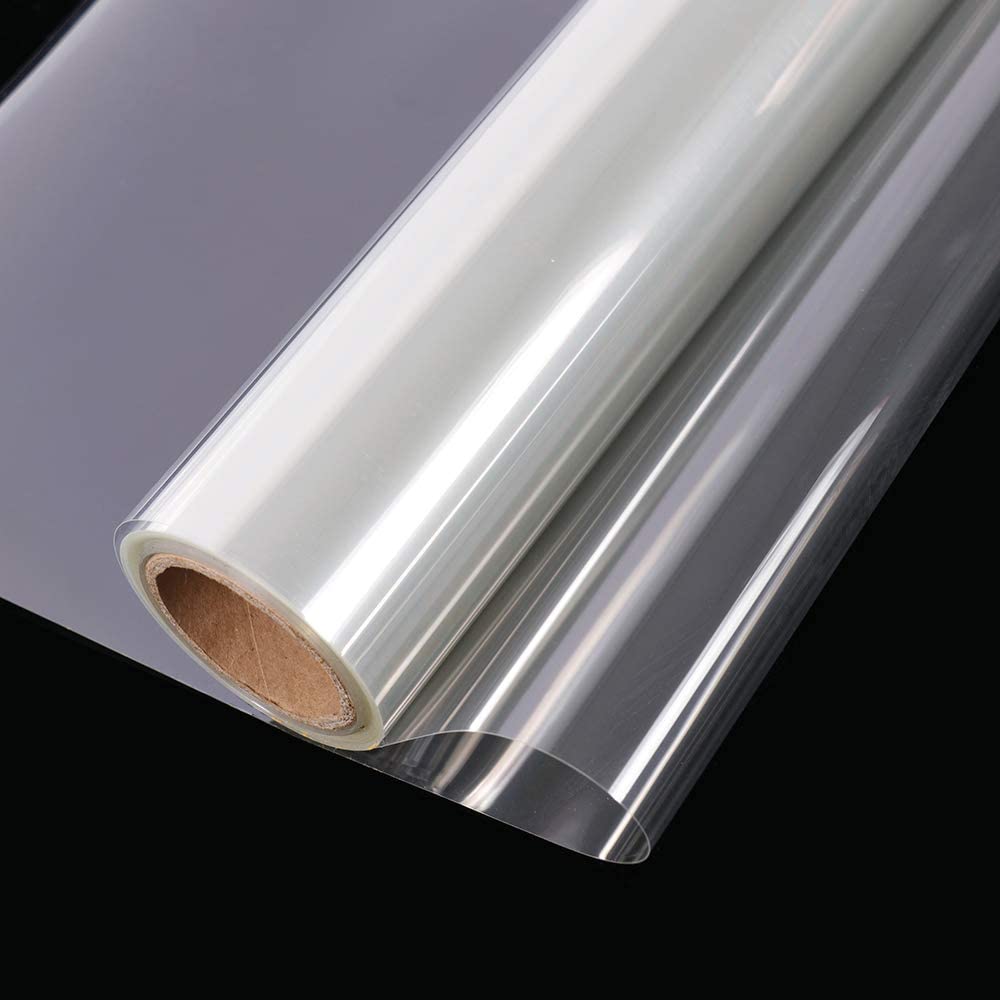

Clear safety and security films are a cost-effective and convenient way to upgrade existing windows without replacing them. They are virtually invisible and scratch-resistant, making them compatible with most non-abrasive cleaning methods.

Moreover, they block out 99% of UV radiation, which reduces the fading and deterioration of vulnerable items like soft furnishings.

The 200-micron safety film has been tested and certified to meet EN 12600 Class 1B1 standards, making it compliant with the latest government regulations for bomb-blast protection. Many government agencies and commercial organizations are now using multi-laminate safety and security films to mitigate the risk of bomb-blast or industrial explosion.

Half or full rolls of safety and security films can be purchased to meet specific requirements.

Safety and Security Window films have many benefits depending on film choice:

Safety and protection

Anti-shatter properties of glass which provides safety and protection.

A cooler working environment

Reduce solar heat gain and temperature inside a building, vessel etc.

Reduction in AC requirements

Reduce air conditioning costs.

Reduction in maintenance

Extend life of HVAC systems by reducing maintenance and strain on the system.

Go Green

Decrease environmental emissions.

Increased comfort

Increase occupant comfort.

Protect exposed areas of the body

Block up to 99% of UV radiation.